News Story

Workshop on Wide Bandgap Power Semiconductors Stresses Need for Commercial Development

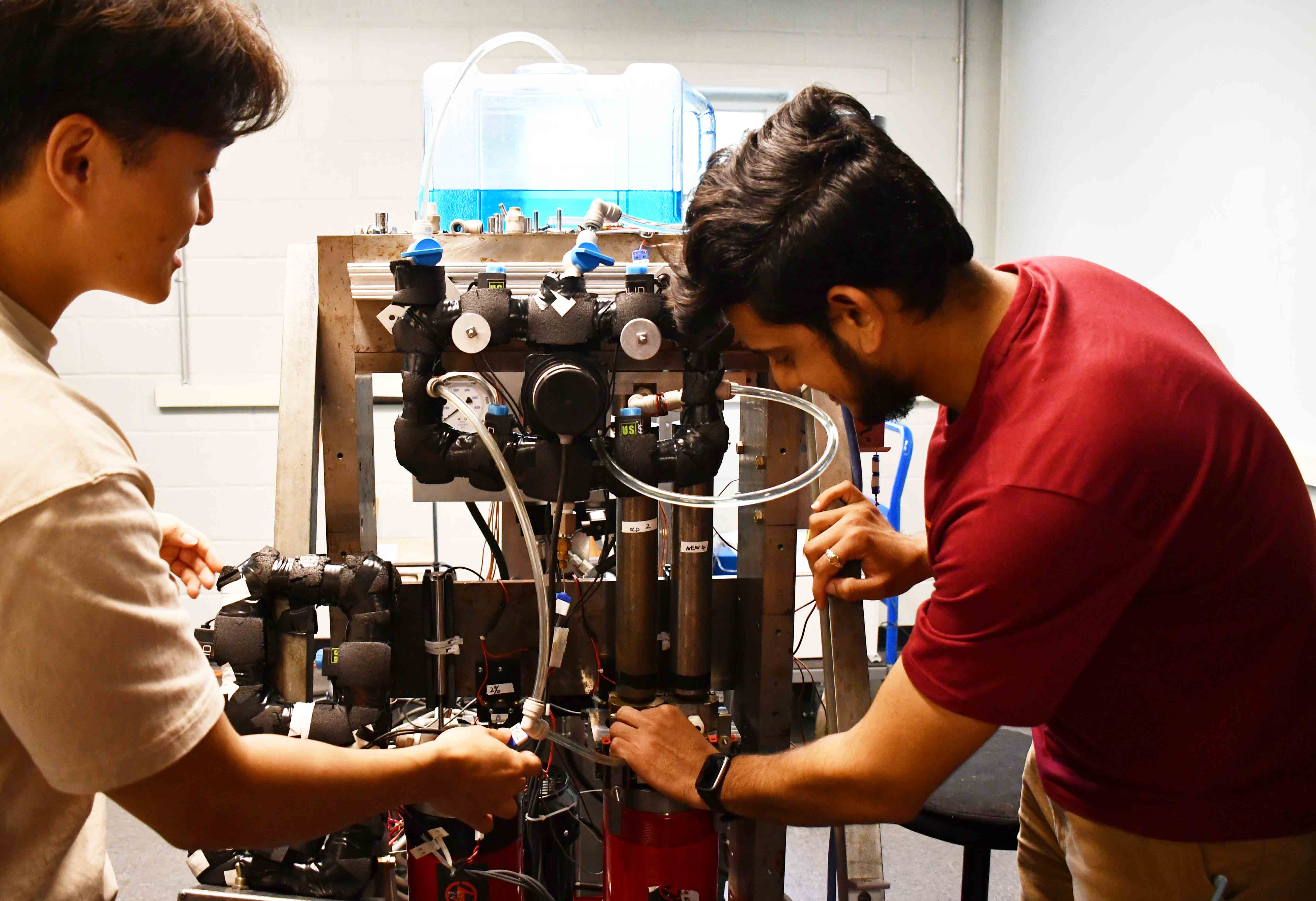

Attendees at the 2012 Robust Wide Bandgap (WBG) Semiconductor Power Electronics Workshop, co-hosted by Argonne National Laboratory and the University of Maryland.

Argonne National Laboratory and the University of Maryland recently co-organized a workshop on wide bandgap (WBG) power semiconductors that brought together over 60 key industry and government stakeholders to facilitate the rapid development of low-cost manufacturing of WBG power devices in the United States. The event was hosted at the Clark School's Jeong H. Kim Engineering Building by Department of Materials Science and Engineering Professor Aris Christou and Krishna Shenai, Argonne's Energy Systems Division's principle engineer.

The event was one of a pair offered by Argonne National Laboratory and the University of Maryland: a workshop held at Argonne, co-sponsored by the Clark School's Center for Advanced Life Cycle Engineering (CALCE), focused on the use of WBG semiconductors for transformative advances in electric utility and transportation infrastructures; while the event at Maryland emphasized WBG products designed to address national security needs. Discussions focused on the key challenges manufacturers face in commercializing WBG power modules, and identifying the nation’s strategic military and space application requirements.

Compared to silicon power devices, WBG power semiconductor materials, such as silicon carbide (SiC) and gallium nitride (GaN), have electronic band gaps significantly larger than one electron volt (eV), and enable power-switching devices to operate at higher temperatures and higher voltages with improved energy conversion efficiency. WBG power electronics converters would be smaller, lightweight, and capable of operating for longer periods of time under the harsh environmental conditions demanded by commercial and national security applications.

According to Christou, one of the workshop's significant outcomes was the recognition that commercial availability and acceptance of WBG power devices have been hindered by high cost, unproven field-reliability, and limited voltage and current ratings.

"[We] concluded that a new WBG manufacturing initiative is required to develop low-cost, reliable technology and novel manufacturing approaches, as well as to enable seamless and transparent interactions among key industry stakeholders in the entire supply chain, from the material manufacturers to end user original equipment manufacturers [OEMs]," Christou explains.

The workshop participants discussed the establishment of an OEM-driven WBG manufacturing consortium in which key industries would collaborate and solve common manufacturing challenges with support from national laboratories, major universities, and community colleges. The goal of the Consortium would be to develop integrated teams to address the challenges identified in the WBG workshop and to rapidly bring WBG power semiconductors to the market and into widespead use.

Published December 3, 2012