Professor Lourdes Salamanca-Riba

The arrival of the JEOL 2100F transmission electron microscope in the NISPLab enabled MSE graduate student Sung Hwan Lim, working under the direction of Professor Lourdes Salamanca-Riba and in collaboration with Professor Ichiro Takeuchi, to observe the effects of varying the partial oxygen pressure during the production of magnetic thin films by pulsed laser deposition. Such materials could form the basis for a diverse array of electronics used in applications ranging from cars to computers. The discovery, which shows that decreasing oxygen pressure leads to a higher magnetization of the film, could allow the creation of inexpensive sensors that respond to both magnetic fields and electrical charges.

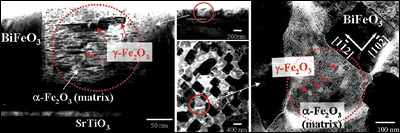

BiFeO3 films grown at low oxygen partial pressure show formation of α- and γ-Fe2O3phases embedded in BiFeO3 matrix. The γ-Fe2O3 phase is responsible for an increase in magnetization in these films. (a) top middle and left cross sectional images; bottom middle and right plan view images from a BiFeO3 film grown at 5 mTorr. (b) and (c) EDS spectra from the two regions in (a) and (d) M-H hysteresis loops for pure BiFeO3 grown at 20 mTorr and multiphase BiFeO3 films grown at 1 mTorr.

To understand the role of processing parameters on the properties of multiferroic thin films of Bi-Fe-O, the research group has performed a systematic study of the structure of these films grown on SrTiO3 substrates. They found that the films with highest magnetization and polarization are grown at low oxygen partial pressures. Transmission electron microscopy shows that films grown at high oxygen partial pressures are pure epitaxial BiFeO3 while films grown at low oxygen partial pressures contain α- and γ-Fe2O3 phases embedded in the BiFeO3 matrix (see figure, top center). Their results show that the observed increase in magnetization is proportional to the amount of ferromagnetic γ-Fe2O3 in the films. The Fe2O3 phases form because the volatile Bi evaporates from the films at low oxygen partial pressure giving rise to regions in the film which are Bi-deficient. These regions transform to α- and γ-Fe2O3 with a 19% reduction in volume. This volume reduction relaxes the strain in the film which arises due to the crystal lattice mismatch between BiFeO3 and SrTiO3. The group’s future work will be to measure the composition profiles across the BiFeO3 and Fe2O3 to determine the reasons for the observed enhancement in the ferroelectric properties of the films.

Supported by the National Science Foundation under MRSEC DMR-00-0520471. The NISP laboratory is a shared experimental facility of the NSF MRSEC at UMD.

Top