Professor Gottlieb S. Oehrlein

Professor Raymond Phaneuf

Two projects funded by the National Science Foundation are aimed at laying a foundation for designing resist masks which are suitable for nanoscale manufacturing with new polymers and plasma processing.

Two projects funded by the National Science Foundation are aimed at laying a foundation for designing resist masks which are suitable for nanoscale manufacturing with new polymers and plasma processing.

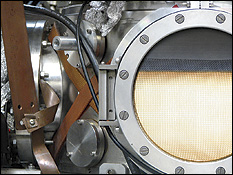

Photolithography and plasma-based transfer of resist patterns to produce devices are part of the basic suite of manufacturing techniques used in information technology, flat panel displays, microsystems, and other devices requiring patterned films or substrates. The extension of current microscale patterning approaches to the nanoscale is made difficult by our lack of understanding of the interaction of the plasma species with the organic macromolecules and the chemical, morphological and topographic changes induced by these interactions. Uncontrolled plasma-macromolecule interactions can produce chemical changes and lead to surface and line edge roughening of the mask pattern, and introduce unacceptable changes in the dimensions of features. The reasons for these changes are not understood, and depend in a complex way on both the properties of the organic mask material, and the reactive particle fluxes in the plasma and detailed parameters of the plasma processing environment.

The goal of the research is to identify and overcome the factors that control the introduction of nanoscale roughness in current technology. The work is being carried out by MSE graduate students Sebastian Engelmann, Robert Bruce, Taesoon Kwon, and Florian Weilnböck, who, working under the supervision of Professors Oehrlein and Phaneuf, also collaborate with visiting scientist Masatoshi Sumiya (Hitachi Incorporated) and researchers at UC Berkeley, UT Austin, Lam Research Corporation, Rohm and Haas Electronic Materials, General Electric Global Research and ITC-IRST, Italy.

Top