News Story

3D Li metal anode provides high energy and improved safety

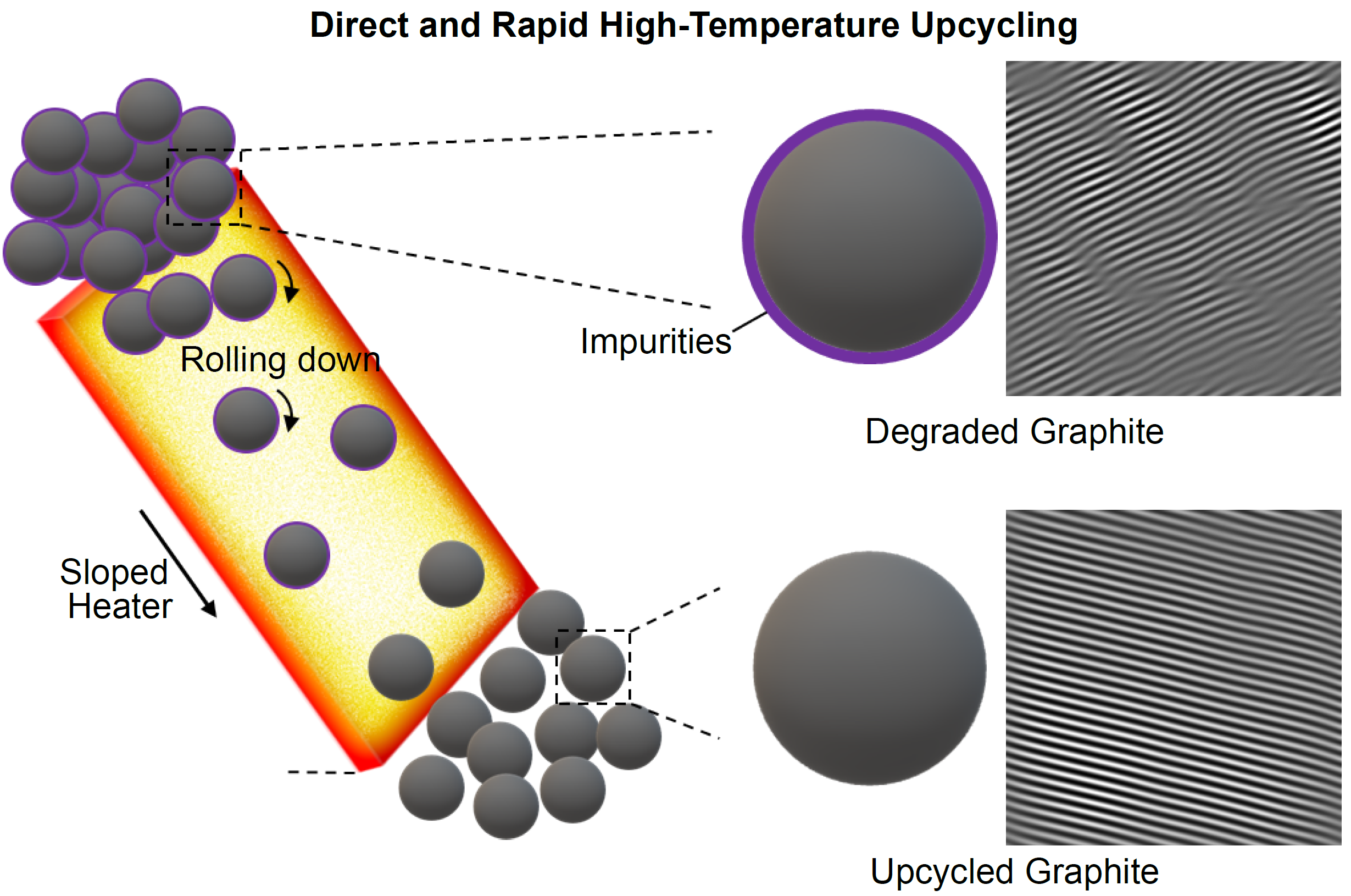

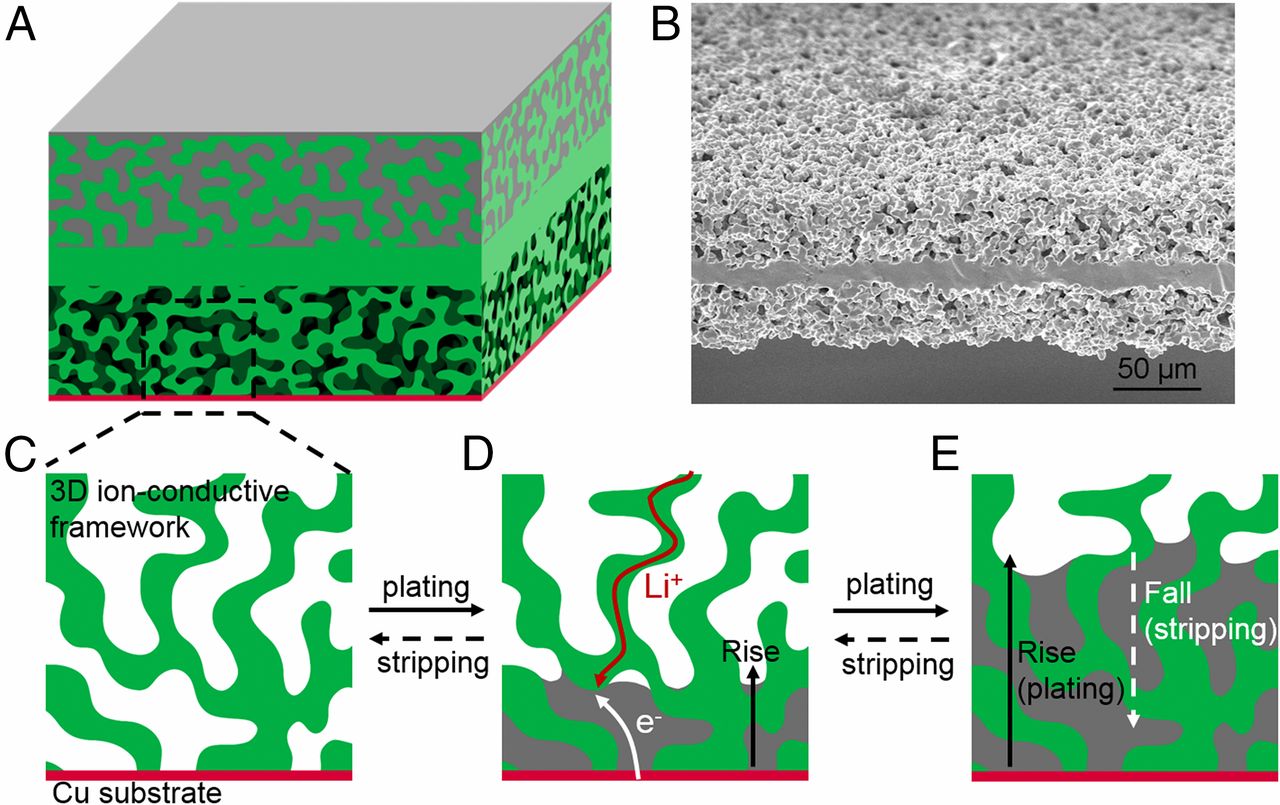

Schematic for the process of Li plating and stripping in the 3D Li-ion-conductive host.

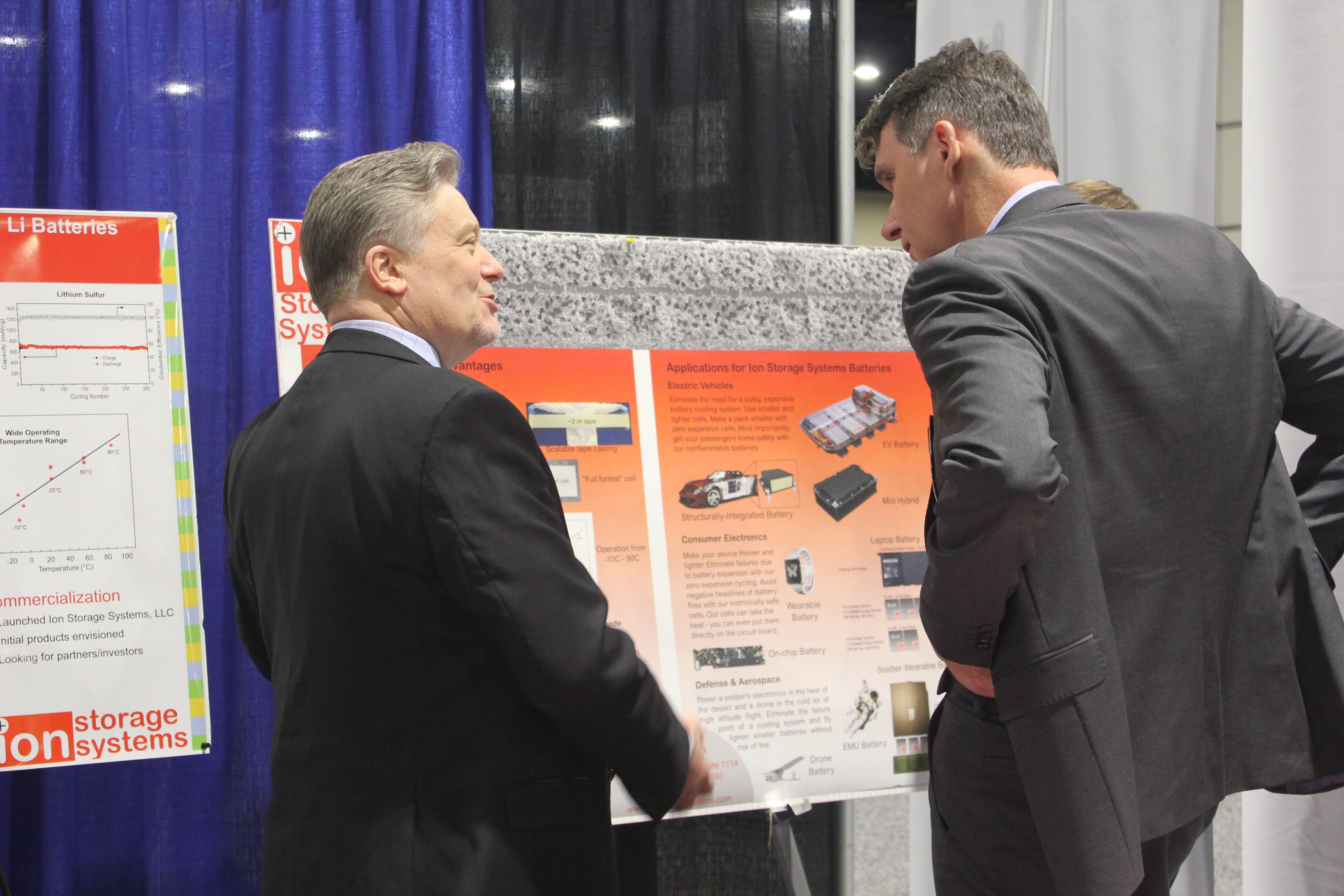

With increased interest in clean energy storage, particularly in the form of battery systems, engineers at the University of Maryland have developed a high-capacity and safe Li metal anode for solid-state high-energy-density batteries. Dr. Liangbing Hu, one of the lead PIs and an associate professor of materials science and engineering said, “This solid state 3D ion conductor with a metal current collector leads to well-controlled stripping and platting of Li metal anode, which provides a new strategy to avoid Li metal dendrites.”Battery energy storage has the capacity to fill in wind and solar power electricity production gaps if safe and clean. For consumer electronics, lithium ion batteries work well because they can be recharged quickly, and they provide a lot of power for their size and weight. However, over time, cycling or reuse of these batteries drastically reduce their performance especially at high voltages.

Dr. Eric Wachsman, Director of the Maryland Energy Innovation Institute (MEI2) and William L. Crentz Centennial Chair in Energy Research said “not only does it provide a novel and safer approach to enable the use of high capacity Li metal anodes, but when paired with high capacity lithiated cathodes removes the need to fabricate cell with excess Li in the anode to further increase energy density and reduce cost.”

The scientists note that by depositing Li metal into the 3D garnet framework with Cu current collector at the bottom, Li metal is plated from the bottom Li metal is plated away from the bottom of the 3D host away from the separating layer and gradually fills the garnet host. Since the Li is initially plated on the bottom current collector away from the separator, any possible penetration through the electrolyte can also be prevented.Potential users include consumer electronics, the defense and aerospace industries as well as electric vehicles.

The research was published in the Proceedings of the National Academy of Sciences and can be found at: www.pnas.org/cgi/doi/10.1073/pnas.1719758115

Published March 27, 2018