News Story

Elastocaloric Cooling System Developed by Clark School Faculty Featured in Science

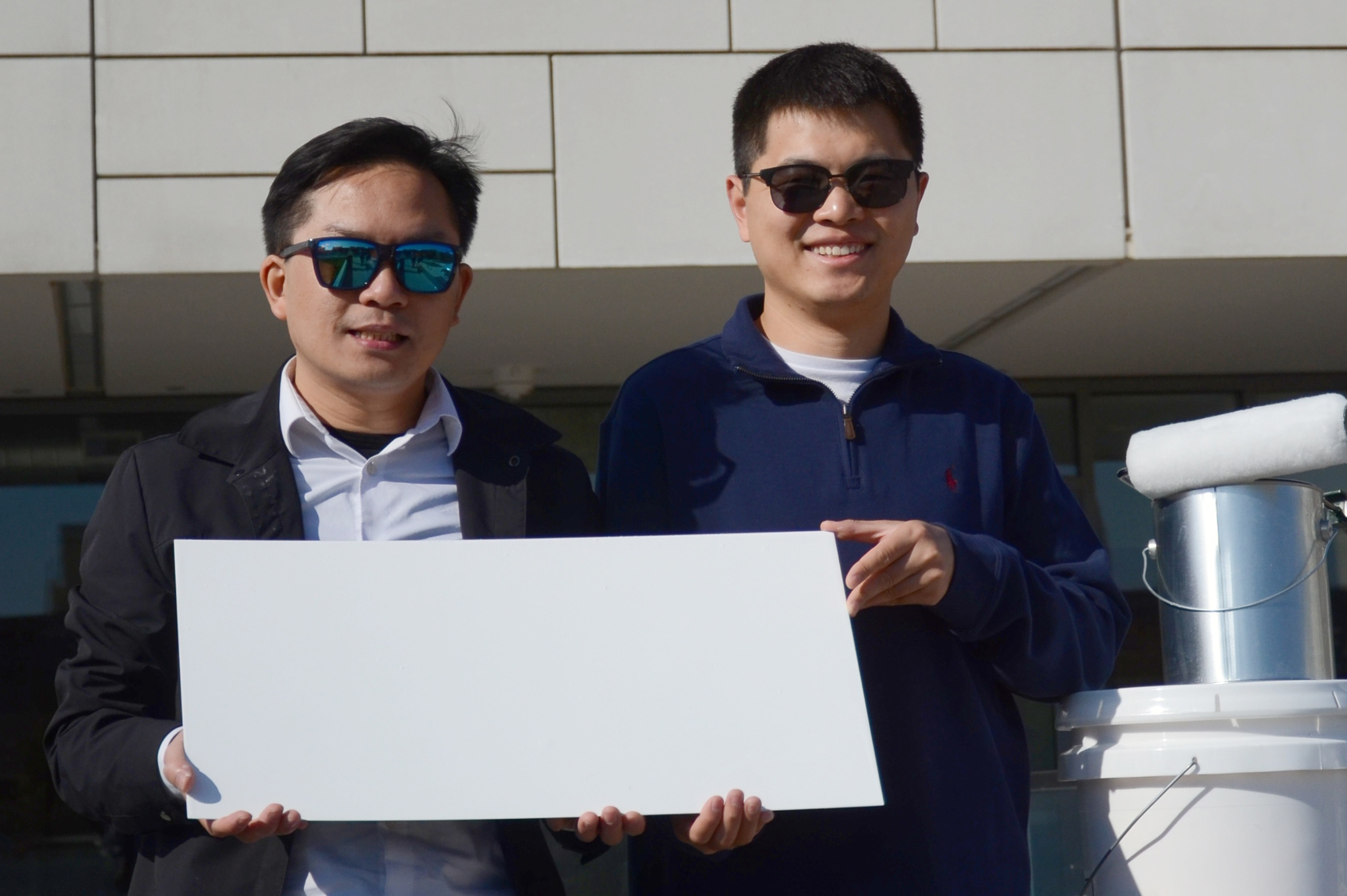

Image credit: Jiaqi Dai

Air conditioning, refrigeration and other cooling technologies account for more than 20 percent of today’s global energy consumption, and hydrofluorocarbons, used as refrigerants in vapor compression systems, have a global warming potential thousands of times greater than carbon dioxide. In the May 18 issue of Science, the team led by Materials Science and Engineering (MSE) Professor Ichiro Takeuchi and Mechanical Engineering (ME) Professors Reinhard Radermacher and Yunho Hwang introduce a high-performance elastocaloric cooling system that not only meets climate change concerns but could represent the next generation of cooling devices.

The article details the work of Takeuchi and his team on what he describes as “a completely different, completely green, environmentally friendly cooling technology.” The paper’s first author, Suxin Quian, PhD ’15, was Radermacher’s first student to work on the project. Second author David Catalini, PhD ’20, followed in those footsteps, working on the design, operation, and testing of the novel cooling system.

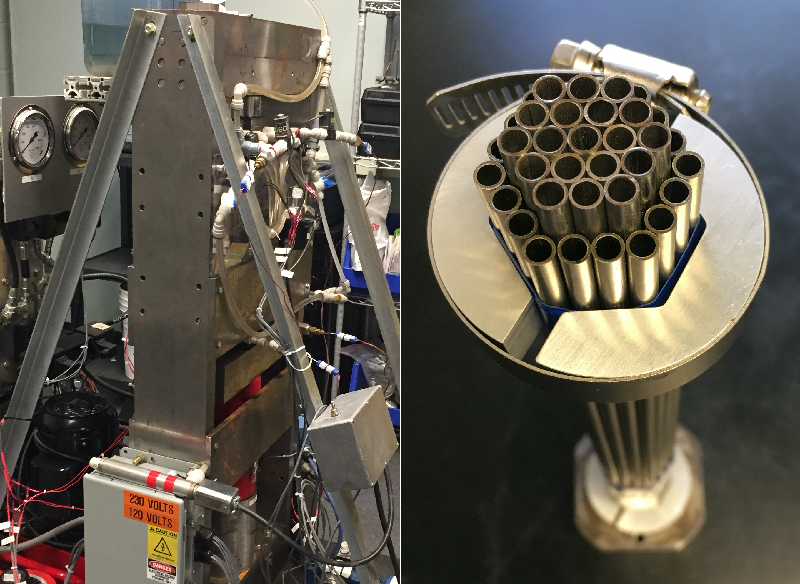

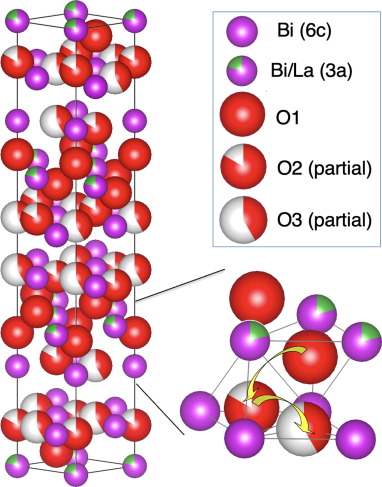

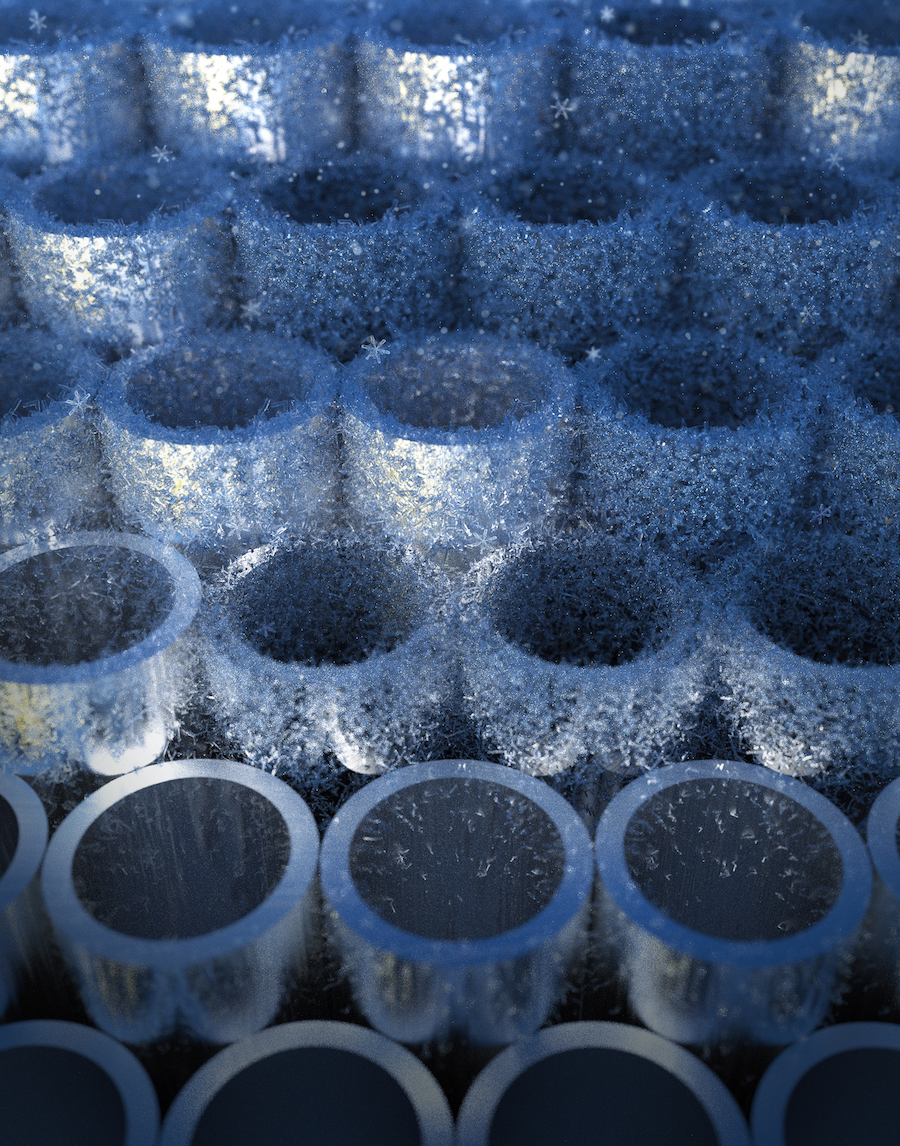

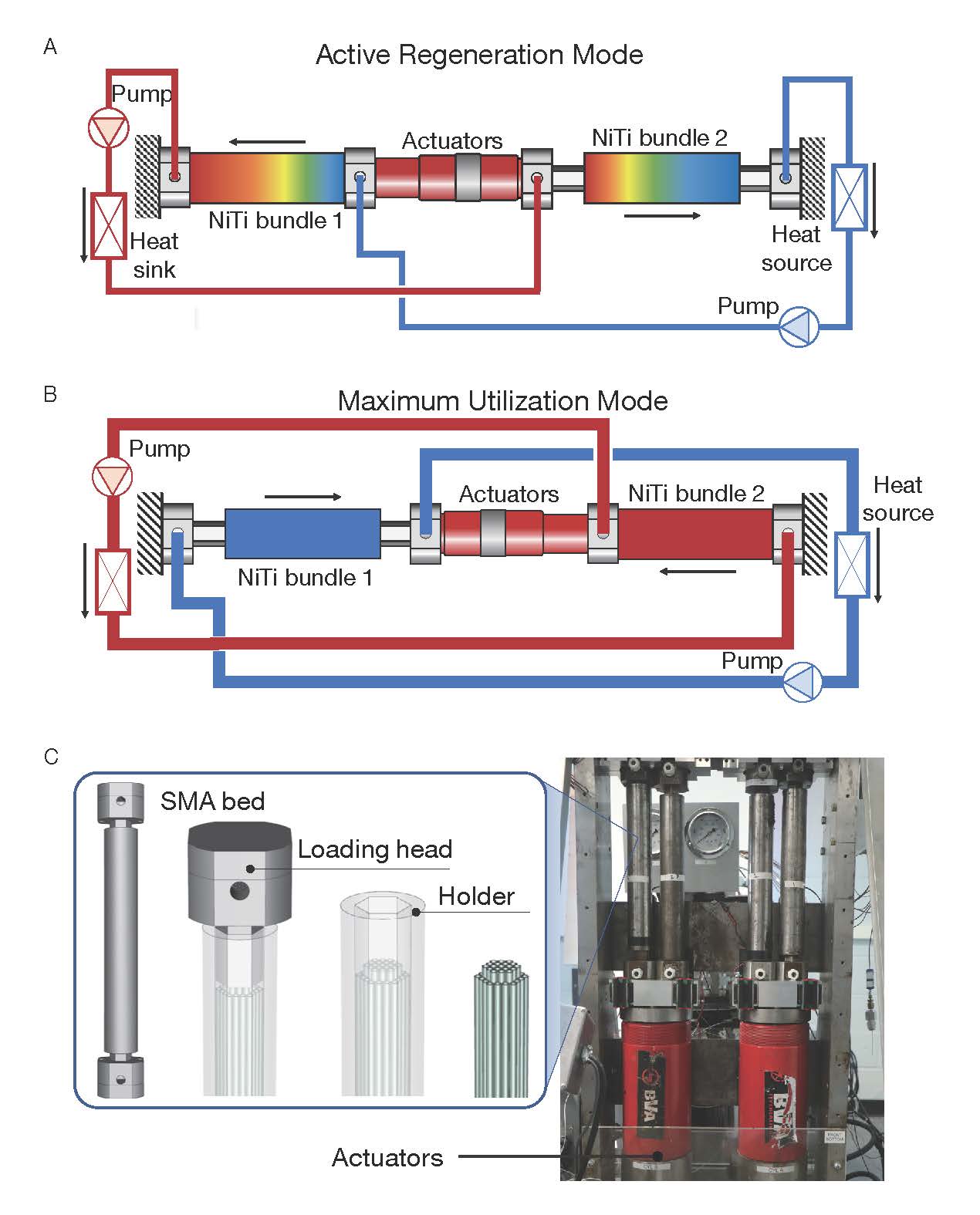

Caloric materials, including magnetocaloric, electrocaloric, and elastocaloric materials can undergo phase transition and release and absorb heat upon application of various fields. The key feature of the elastocaloric system is the compression and release of fatigue-resistant nitinol (NiTi) tubes configured in a versatile, multimode heat exchange architecture. To make such materials commercially viable, they must meet steep requirements: a sufficient cooling power, superior energy efficiency, enough failure resistance, adequate availability of ingredients, and a low cost.

“More than a decade ago, we were just playing with a NiTi wire,” describes Takeuchi. “By stretching it, you could get a substantial cooling effect one could feel by hand. That was when we started thinking about applying the concept to a cooling device.” For more than ten years, the lab’s work has been funded by the U.S. Department of Energy.

In the recent Science article, Takeuchi’s team noted, “To capture the best aspects of the active regeneration cycle and the large utilization operation in a single practical prototype, we developed a multimode elastocaloric cooling system leveraging the large temperature span of the active regeneration mode and the efficient cooling of the maximum utilization mode. In the prototype, the two modes can be easily switched from one to the other by controlling the operation sequences of valves in the heat exchange fluid network.”

With the new technology, the materials remain in a solid state as compared to traditional refrigerants, like hydrofluorocarbons, that work by shifting gas and liquid phases. The new system has a cooling power of 260 watts of useful cooling power and a maximum temperature span of 22.5 kelvin---among the highest reported for any caloric cooling system.

“Our technology, developed in the last eight years, has been able to demonstrate devices and systems that can perform at the same level as magnetocaloric systems, which have been around since the 1980s,” says Takeuchi. The team is now working on achieving higher performance and a larger temperature lift from the device as well as identifying a softer material to achieve the same effect with a substantially lower force or stress.

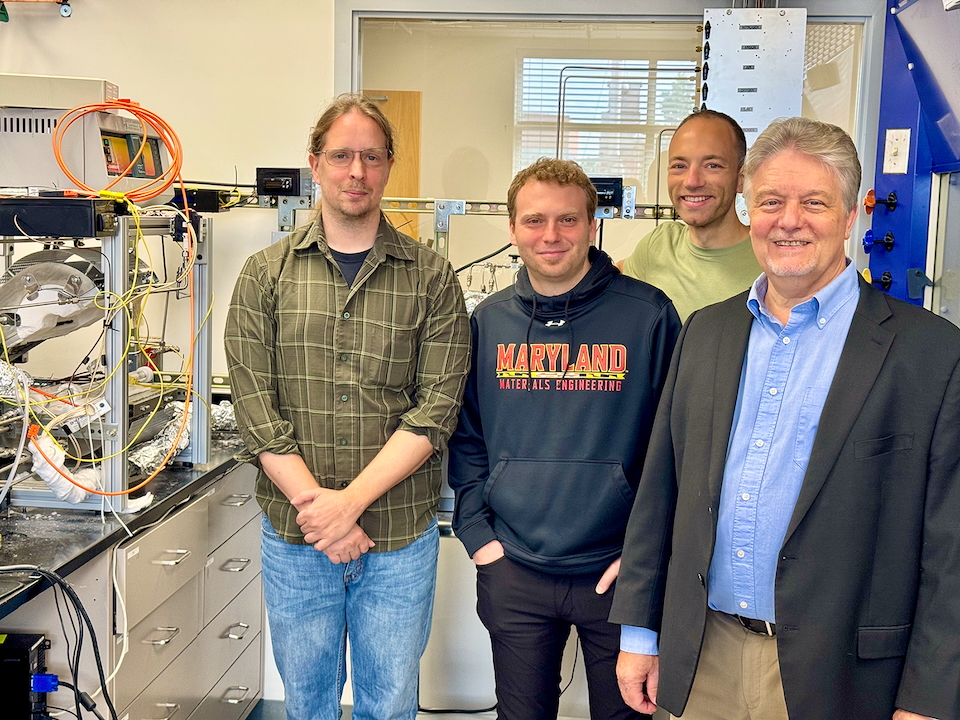

A major reason for the rapid progress is the collaboration between the Department of Materials Science and the Center for Environmental Energy Engineering (CEEE), headed by Radermacher. “We have the perfect marriage between our two departments. We observed the qualities of the material, but we could not move forward without the device and system expertise the CEEE provides,” says Takeuchi. “Many other groups can only focus on one aspect or another. The Clark School’s multidisciplinary approach allows us to continue to play a leadership role in the field,” says Radermacher.

A major reason for the rapid progress is the collaboration between the Department of Materials Science and the Center for Environmental Energy Engineering (CEEE), headed by Radermacher. “We have the perfect marriage between our two departments. We observed the qualities of the material, but we could not move forward without the device and system expertise the CEEE provides,” says Takeuchi. “Many other groups can only focus on one aspect or another. The Clark School’s multidisciplinary approach allows us to continue to play a leadership role in the field,” says Radermacher.

“Twenty years ago, we were validating a phase transformation theory, working on a different aspect of the same material to optimize a shape memory alloy—an actuator material-- to extend fatigue life,” explains Takeuchi. “The key to delivering competitive commercial devices is identifying affordable materials that can undergo large temperature shifts, easily revert back, and withstand extended, in some cases millions of, cycles without breaking down.

The team’s calculations indicate that the system’s overall efficiency could be improved by a factor of 6 by using more efficient actuators. Additionally, the researchers are hoping to improve efficiency by switching the NiTi with a known copper-based material that exhibits a similar elastocaloric temperature change under smaller stress.

Takeuchi believes that he and his colleagues can improve the performance of their system enough to make the technology commercially viable within several years. A current prototype can produce 200 watts of cooling capacity, enough to power a compact wine fridge, and team hopes to expand to window units, whole-house cooling systems, and commercial HVACs eventually.

For more information:

- Suxin Qian et al., High-performance multimode elastocaloric cooling system.Science,380, 722-727 (2023).DOI:10.1126/science.adg7043

Published June 6, 2023