News Story

Super Wood Could Replace Steel

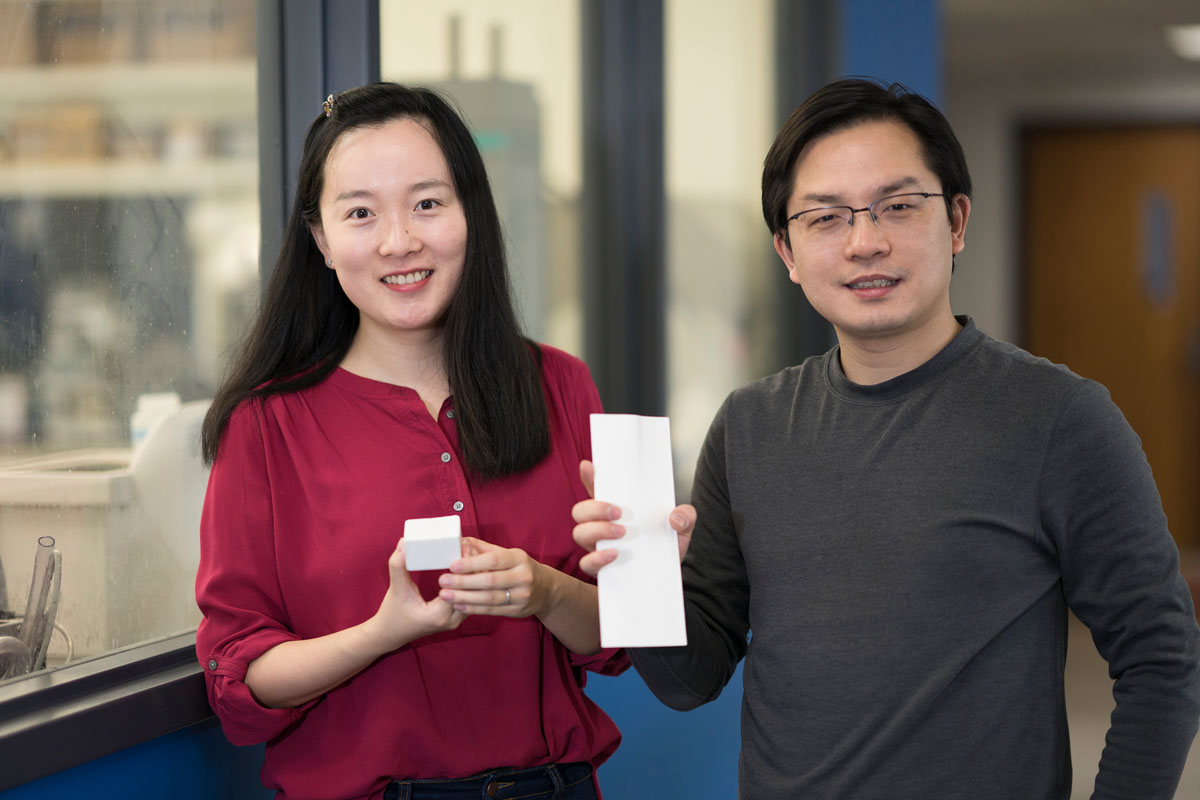

COLLEGE PARK -- Engineers at the University of Maryland in College Park have found a way to make wood more than ten times times stronger and tougher than before, creating a natural substance that is stronger than titanium alloy.

“This new way to treat wood makes it twelve times stronger than natural wood and ten times tougher,” said Liangbing Hu, the leader of the team that did the research, to be published on Thursday in the journal Nature. “This could be a competitor to steel or even titanium alloys, it is so strong and durable. It’s also comparable to carbon fiber, but much less expensive.” Hu is an associate professor of materials science and engineering and a member of the Maryland Energy Innovation Institute.

“It is both strong and tough, which is a combination not usually found in nature,” said Teng Li, the co-leader of the team and the Samuel P. Langley associate professor of mechanical engineering at the University of Maryland. His team measured the dense wood’s mechanical properties. “It is as strong as steel, but six times lighter. It takes 10 times more energy to fracture than natural wood. It can even be bent and molded at the beginning of the process.”

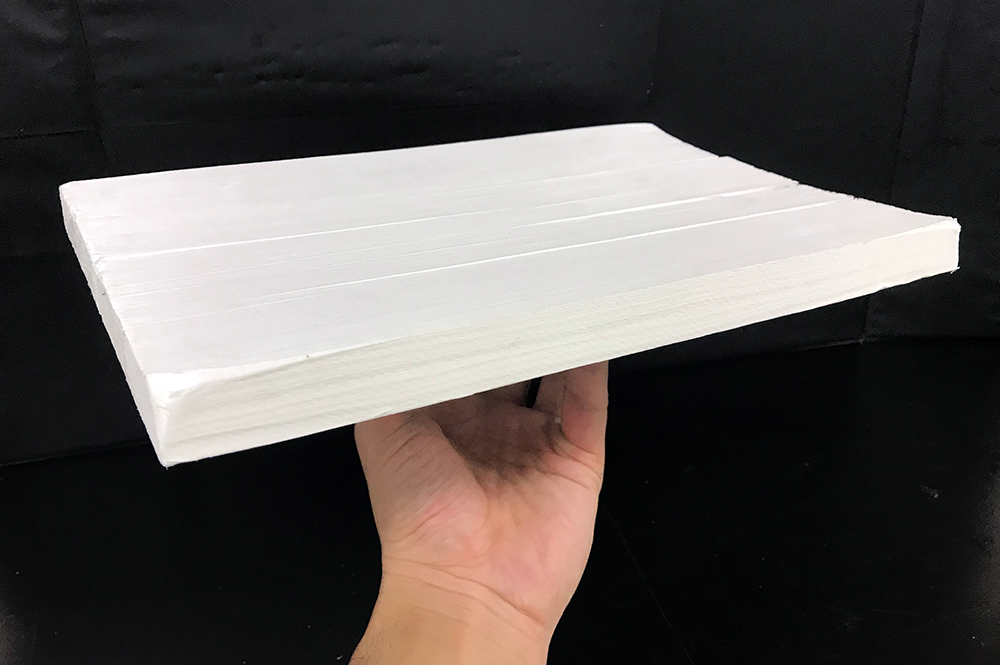

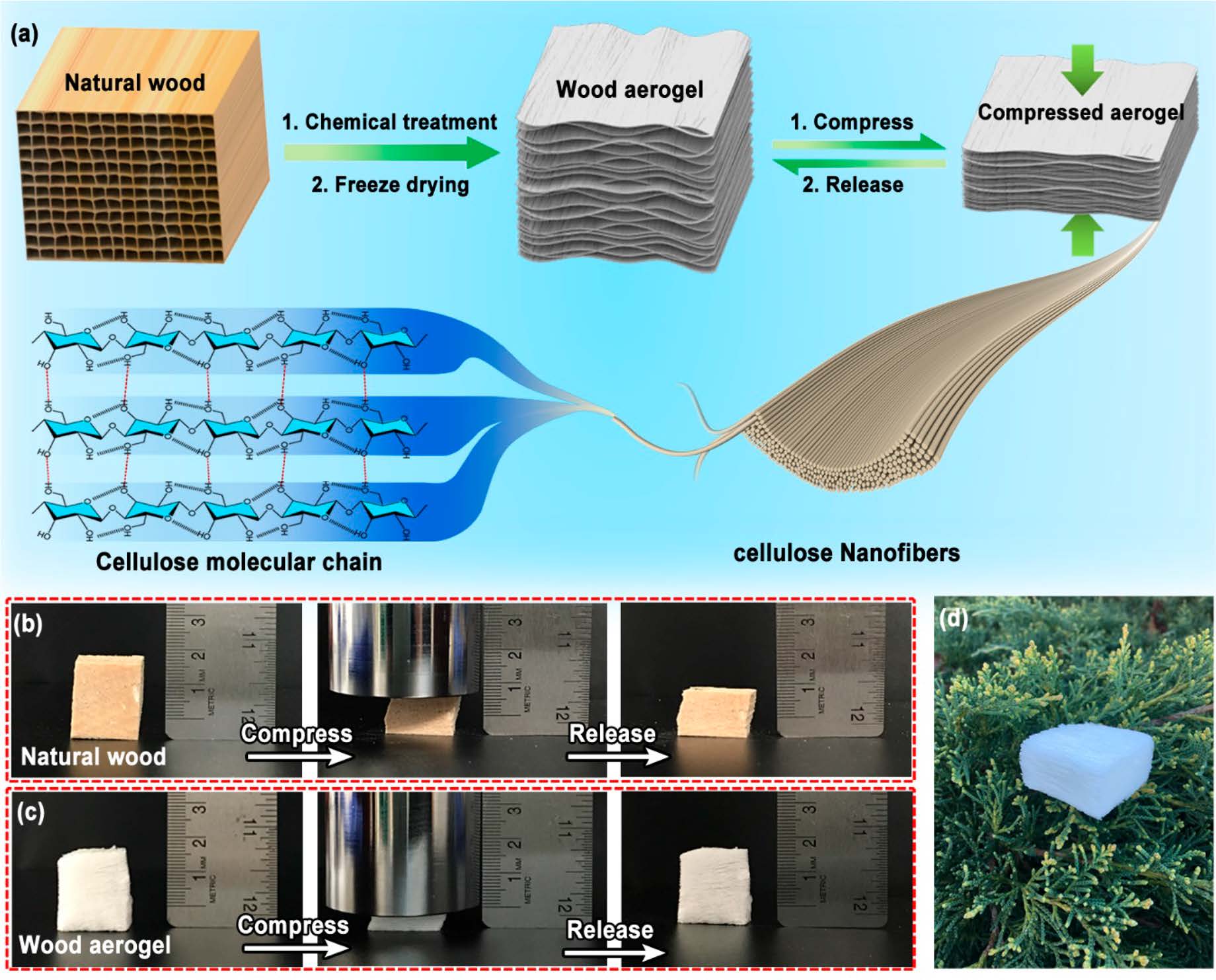

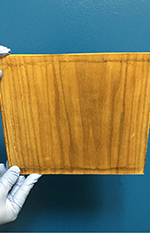

The team’s process begins by removing the wood’s lignin, the part of the wood that makes it both rigid and brown in color. Then it is compressed under mild heat, at about 150 F. This causes the cellulose fibers to become very tightly packed. Any defects like holes or knots are crushed together. The treatment process was extended a little further with a coat of paint.

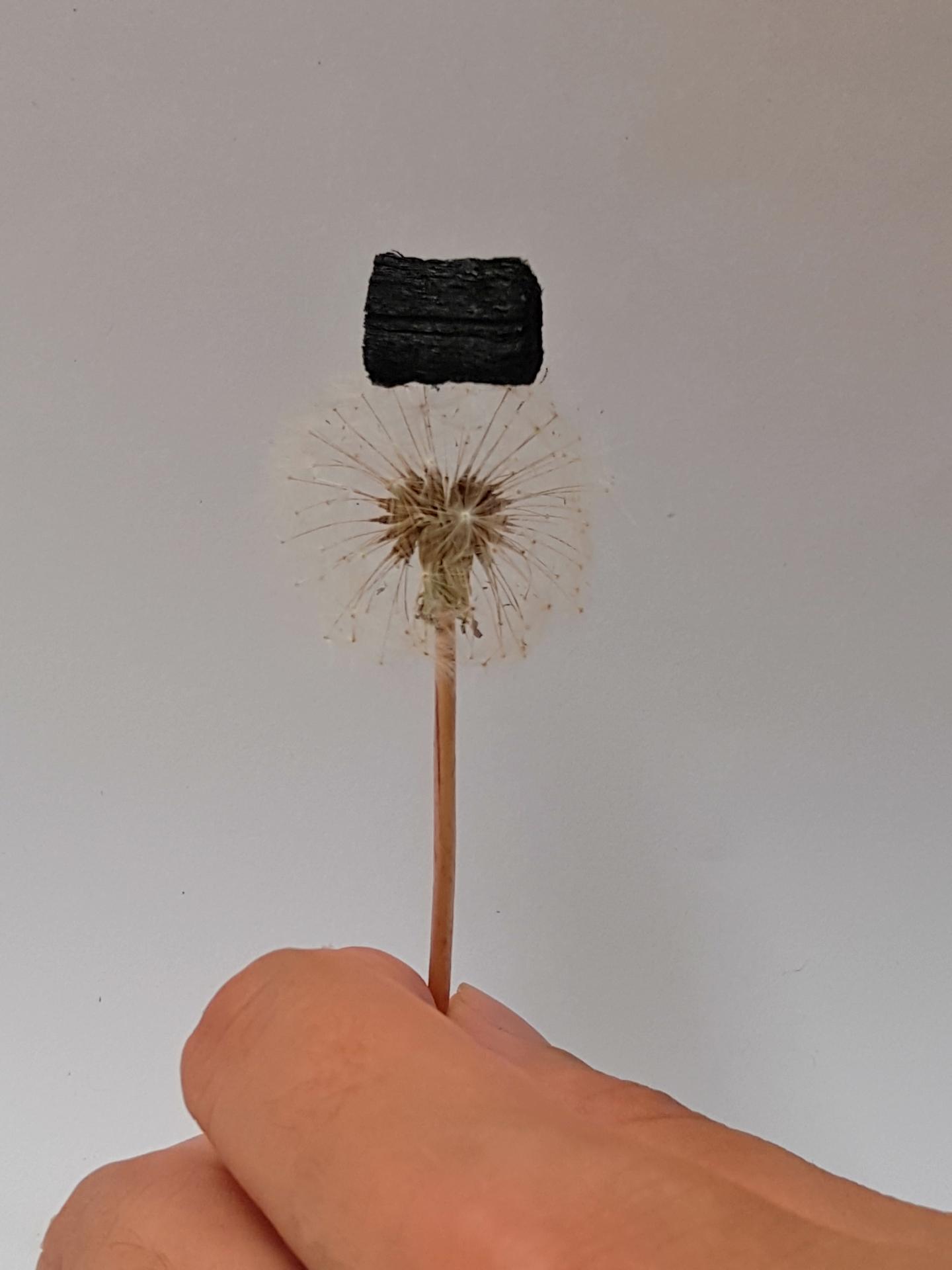

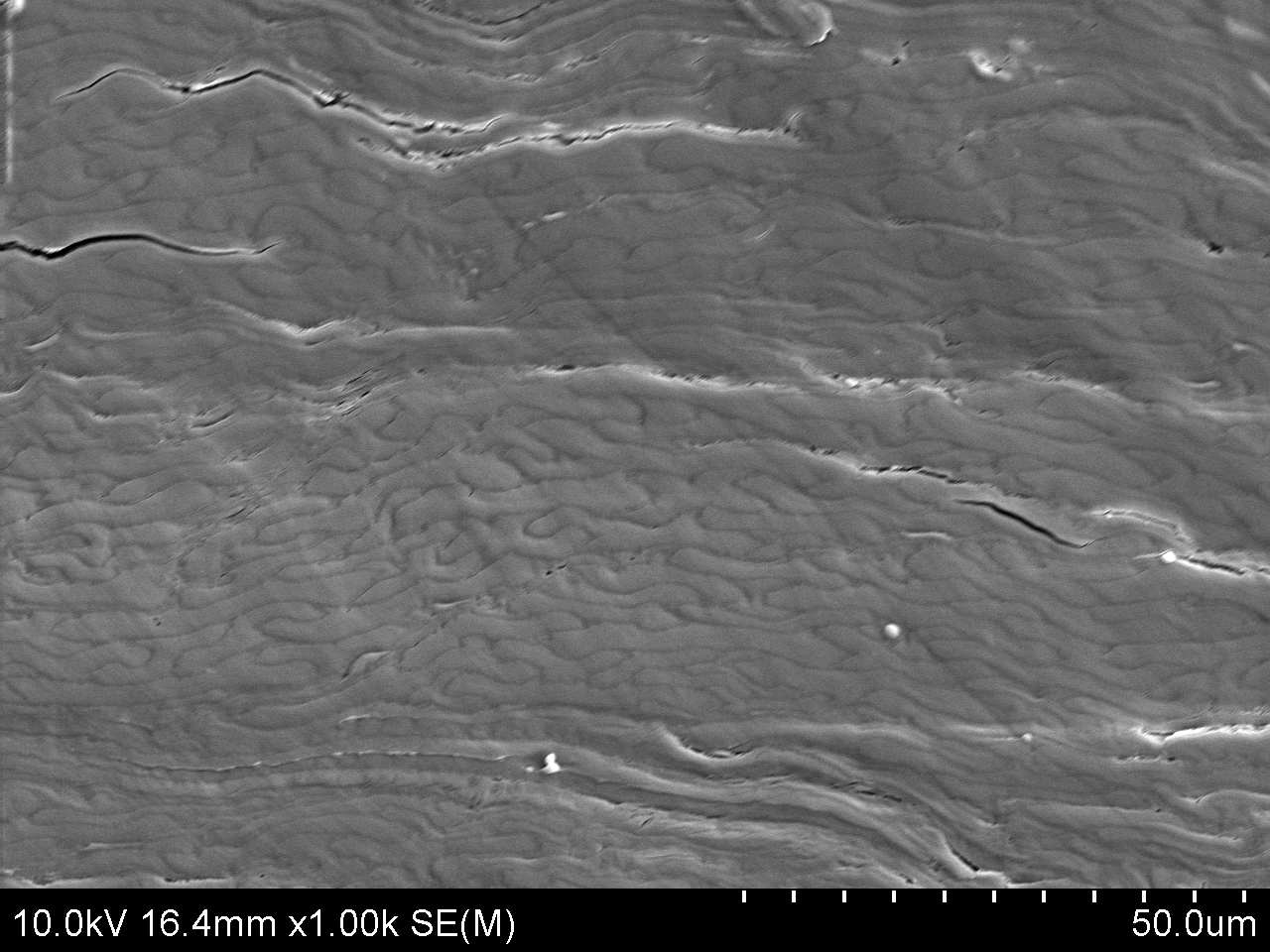

The scientists found that the wood’s fibers are pressed together so tightly that they can form strong hydrogen bonds, like a crowd of people who can’t budge – who are also holding hands. The compression makes the wood five times thinner than its original size.

The team also tested the material by shooting a bullet-like projectile at it. Unlike natural wood, which was blown straight through, the fully treated wood actually stopped the projectile partway through.

“Soft woods like pine or balsa, which grow fast and are more environmentally friendly, could replace slower-growing but denser woods like teak, in furniture or buildings,” Hu said.

“The paper provides a highly promising route to the design of light weight high performance structural materials, with tremendous potential for a broad range of applications where high strength, large toughness and superior ballistic resistance are desired, “ said Dr. Huajian Gao, a professor at Brown University, who was not involved in the study. “It is particularly exciting to note that the method is versatile for various species of wood and fairly easy to implement.”

“This kind of wood could be used in cars, airplanes, buildings – any application where steel is used,” Hu said.

“The two-step process reported in this paper achieves exceptionally high strength, much beyond what [is] reported in the literature,” said Dr. Zhigang Suo, a professor of mechanics and materials at Harvard University, also not involved with the study. “Given the abundance of wood, as well as other cellulose-rich plants, this paper inspires imagination.”

“The most outstanding observation, in my view, is the existence of a limiting concentration of lignin, the glue between wood cells, to maximize the mechanical performance of the densified wood. Too little or too much removal lower the strength compared to a maximum value achieved at intermediate or partial lignin removal. This reveals the subtle balance between hydrogen bonding and the adhesion imparted by such polyphenolic compound. Moreover, of outstanding interest, is the fact that that wood densification leads to both, increased strength and toughness, two properties that usually offset each other,” said Orlando J. Rojas, a professor at Aalto University in Finland.

Hu’s research has explored the capacities of wood’s natural nanotechnology. They previously made a range of emerging technologies out of nanocellulose related materials: (1) super clear paper for replacing plastic; (2) photonic paper for improving solar cell efficiency by 30%; (3) a battery and a supercapacitor out of wood; (4) a battery from a leaf; (5) transparent wood for energy efficient buildings; (6) solar water desalination for drinking and specifically filtering out toxic dyes. These wood-based emerging technologies are being commercialized through a UMD spinoff company, Inventwood LLC.

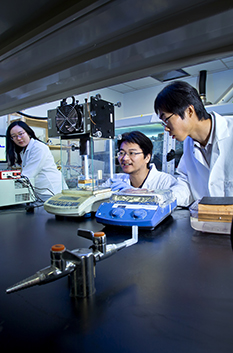

Photos of the wood's microstructures were produced in the Advanced Imaging and Microscopy (AIM) Lab, part of the Maryland NanoCenter, which is headquartered in College Park.

Processing bulk natural wood into a high-performance structural material

J Song, et al.

Nature, 2018

DOI: 10.1038/nature25476

Published February 7, 2018