Press Release

UMD Research Team Develops Compact Solid State Cooling Technology

FOR IMMEDIATE RELEASE October 4, 2018

CONTACT:

Katie Doyle

301 405 0379

khollan3@umd.edu

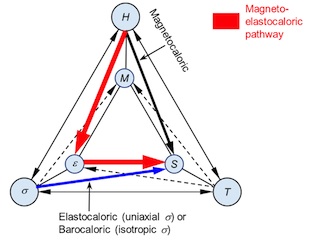

A modified Heckmann diagram illustrating the pathway leveraging magnetic field for cooling in a multiferroic composite. Symbols: magnetic field (H), magnetization (M), stress, strain (E), temperature (T), and entropy (S). Red arrow is the composite magneto-elastocaloric pathway demonstrated in this work, while black and blue arrows are intrinsic magnetocaloric and mechanocaloric (elastocaloric under uniaxial or barocaloric under isotropic) pathways.

A research team in the University of Maryland (UMD) Department of Materials Science and Engineering (MSE) has developed a novel compact solid-state cooling device, which can be used to prevent household electronics - such as laptops - from heating up, or even to treat epilepsy via local cooling of the human brain.

'Caloric cooling' is an emerging field of 'green cooling,' which is making current refrigeration technology, via vapor compression, obsolete. Vapor compression uses chemical refrigerants, which are environmentally hazardous, whereas caloric cooling, uses high-efficiency, solid-state cooling materials. Two types of caloric cooling are magnetocaloric and elastocaloric, which use magnetic fields and mechanical stress (~150 MPa in this case) to induce cooling in various materials.

Until recently, caloric cooling technology - though 'green' and efficient - still boasted numerous challenges, delaying widespread commercialization. Magnetocaloric cooling materials, for example, require very large magnetic fields, which can only be supplied by expensive, permanent magnets. Likewise, existing elastocaloric materials suffer from the requirement of hefty mechanical force.

Ichiro Takeuchi, a professor of Materials Science and Engineering at UMD, and his group have developed a new kind of composite caloric device, which combines the magnetocaloric and elastocaloric effects. A temperature change as large as 4K can be generated with 0.16 Tesla; more than a factor of 10 lower than the level required for typical magnetocaloric materials.

"By integrating a magnetostrictive material called Terfenol-D and a Cu-based shape memory alloy, we are able to demonstrate ultra-low-field magnetic-field induced cooling for the first time," said Takeuchi. "Due to its unique mechanism arising from a composite effect, we call it the magneto-elastocaloric effect."

Terfenol-D is a mixture of iron - which is very rigid - and terbium - which is so soft it can be cut with a knife. Mixing of the two elements into TbFe2 creates a magnetic function, so that Terfenol-D is responsive to magnetic fields.

"The Terfenol-D extends when a magnetic field is applied to it, and retracts upon removal of the magnetic field, a property called magnetostriction," Takeuchi explained. "Adding dysprosium to the original formulation lowers the required amplitude of magnetic field, which is attractive for transduction technologies."

Magnetostrictive technology is used to build actuators and sensors, such as underwater sonar and energy harvesting devices. In gadgets - portable sound systems, for example - magnetostriction is used for sound wave compression.

The device will look like a hand-held gadget, similar in size to a flashlight. Together with its auxiliary components, the device will be portable, easy-to-use, inexpensive and boast broad application.

"Because our composite device is naturally compact, we believe it will open up new cooling applications for caloric cooling, which had not been possible before," said Huilong Hou, a post-doctoral researcher in Materials Science and Engineering at UMD and first author on the study.

This research was published October 4, 2018, in Nature Communications. For additional information: Hou, H., Finkel, P., Staruch, M., Cui, J., Takeuchi, I. "Ultra-low-field magneto-elastocaloric cooling in a multiferroic composite device," Nature Communications, DOI: 10.1038/s41467-018-06626-y.

About the A. James Clark School of Engineering

The University of Maryland’s A. James Clark School of Engineering is a premier program, ranked among the top 20 in the world. Located just a few miles from Washington, D.C., the Clark School is at the center of a constellation of high-tech companies and federal laboratories, offering students and faculty access to unique professional opportunities.

Our broad spectrum of academic programs, including the world’s only accredited undergraduate fire protection engineering program, is complemented by a vibrant entrepreneurial ecosystem, early hands-on educational experiences, and participation in national and international competitions.

The Clark School is leading research advancements in aerospace, bioengineering, robotics, nanotechnology, disaster resilience, energy and sustainability, and cybersecurity. From the universal product code to satellite radio, SMS text messaging to the implantable insulin pump, our students, faculty, and alumni are engineering life-changing innovations for millions. Learn more at www.eng.umd.edu.