News Story

Bruce Wins 2009 AVS Student Merit Award

Bobby Bruce.

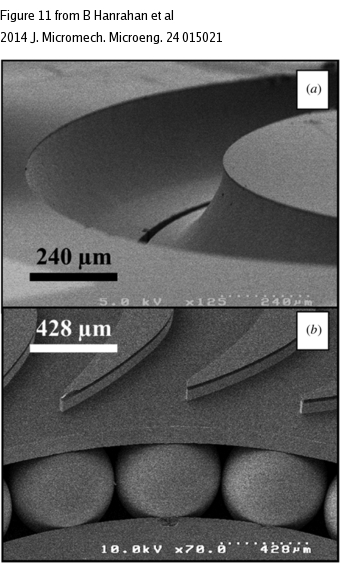

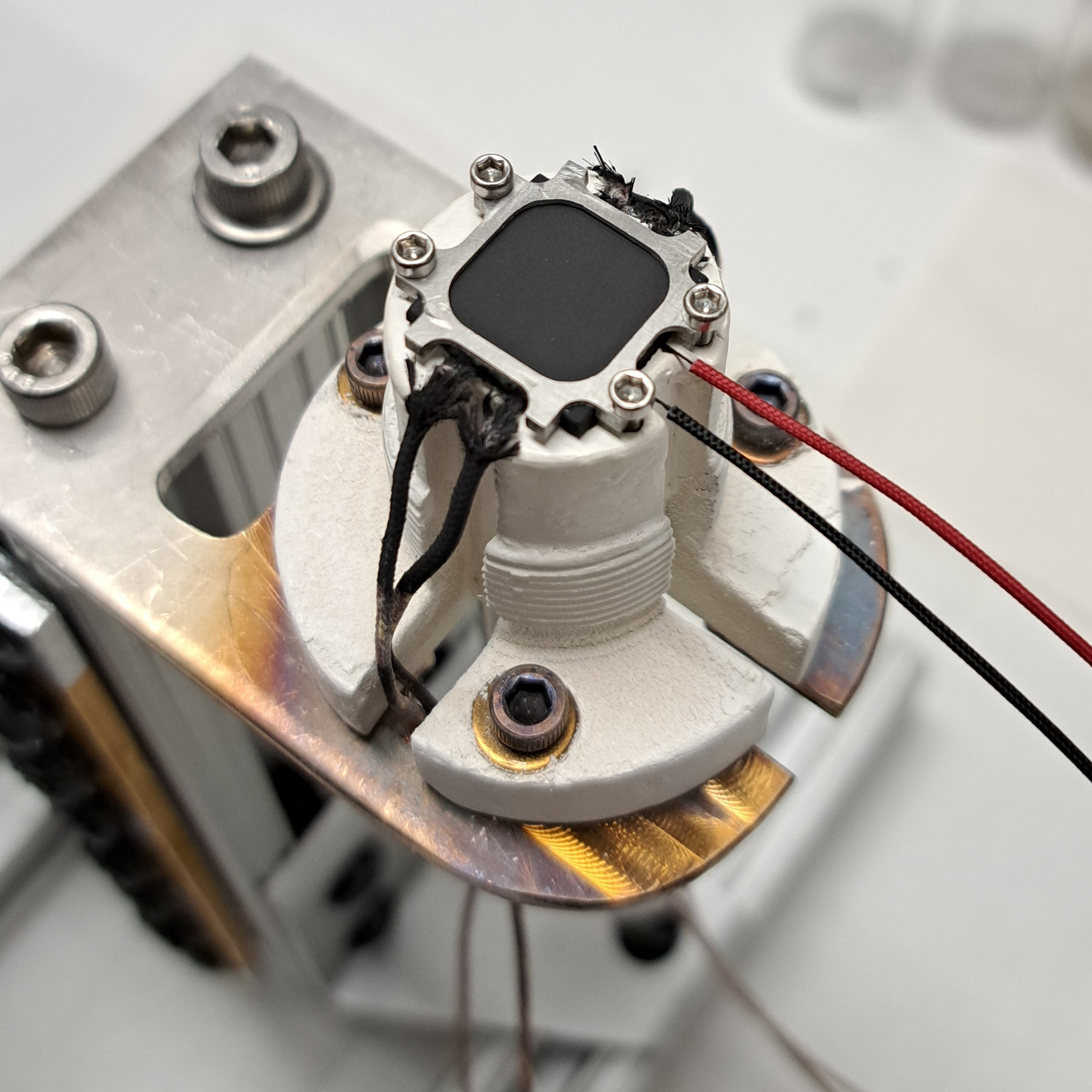

Bruce's winning presentation, titled “On the Absence of Post-Plasma Etch Surface and Line Edge Roughness in Vinylpyridine Resists," described his research on the origin of plasma (super-heated gas)-induced surface roughness in polymer films used in the manufacturing of integrated circuits, and how both polymer structure and plasma processing parameters affect polymer roughening. His work has provided a deeper understanding of how plasma interaction impacts the mechanical properties of polymers' surfaces, and how these changes directly lead to surface roughness.

The research is particularly important to the electronics manufacturing industry. "When you use a polymer mask as a stencil to create patterned nanostructures in something like a computer processor," Bruce explains, "the plasma used to etch the pattern is so intense that it only takes seconds before the mask starts to erode. This is what creates the rough edges on the mask and degrades the quality of the transferred pattern. By selecting the appropriate material for the polymer mask or by tuning the plasma process to be gentler on the polymer we can improve the mask performance. What we learn from our research will help establish a framework of correct design criteria that can be applied to different manufacturing situations."

Cleaner, sharper masks with finer details could be used to create more sophisticated patterns for integrated circuits, which in turn could mean computers that are faster, have higher storage capacities, and produce less heat.

"The roughening problem currently limits the size and performance of the nanostructures we want to manufacture," says Bruce. "Understanding and controlling plasma-induced polymer surface roughness would be highly beneficial for nanofabrication and nanotechnology in general."

For More Information:

Visit Professor Oehrlein's Laboratory for Plasma Processing of Materials web site »

Published December 2, 2009