News Story

Cooling Wood: An Eco-Friendly Building Material

Liangbing Hu and team members Tian Li and Shuaiming He stand in front of the natural inspiration for their new heat-shedding Cooling Wood.

In the race to save energy, using a passive cooling method that requires no electricity and is built into the walls of a house could save even chilly areas of the U.S. some cash. To that end, researchers at the University of Maryland (UMD) and the University of Colorado Boulder have utilized nanotechnology to find a passive way for buildings to dump heat that is also sustainable and strong.

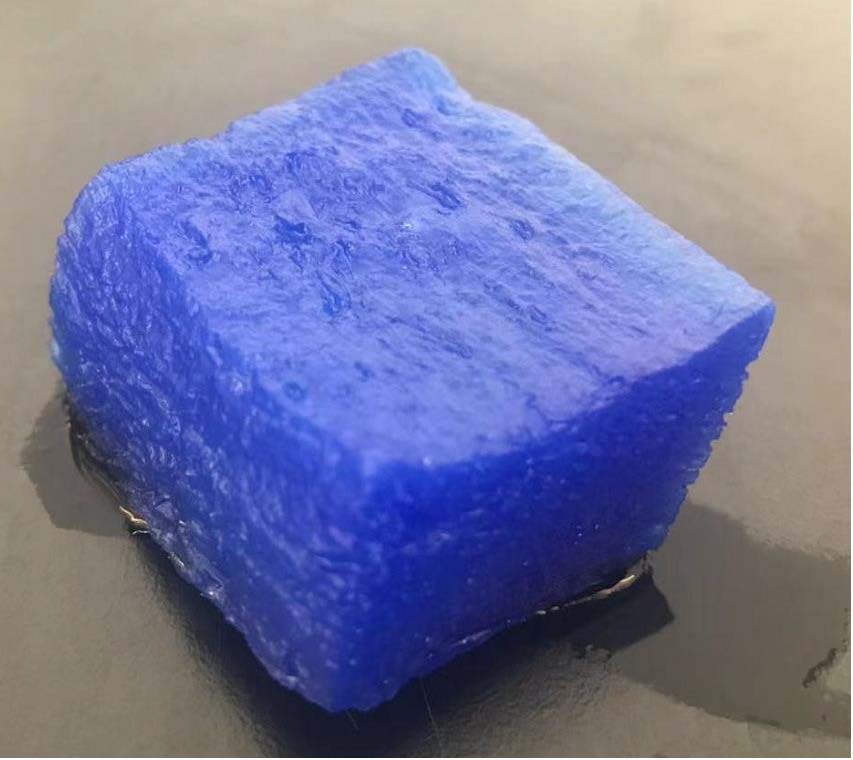

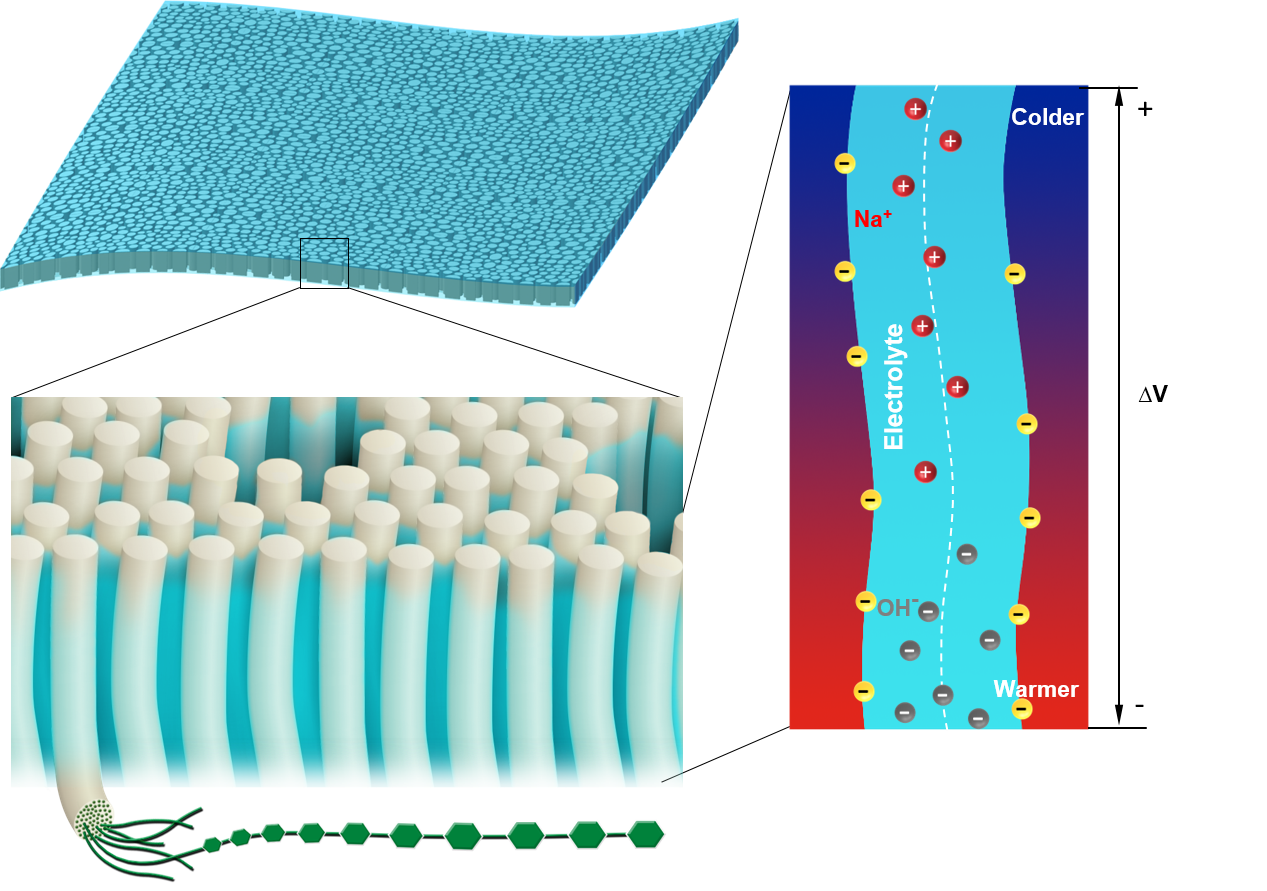

Wood, as a renewable and sustainable materials, solves the problem. Using tiny structures found inside a living tree – cellulose nanofibers and the natural chambers that pass water and nutrients up and down a trunk – the research team specially processed wood pieces with optical properties that radiate heat away. The results of their study were published May 9 in the journal, Science.

“This work has greatly extended the use of wood towards high performance energy efficient applications and provided a sustainable route to combat the energy crisis,” said Jian Li, a Northeast Forestry University Professor who is unaffiliated with the research.

Liangbing Hu – a professor of Materials Science and Engineering (MSE) at UMD – and co-first authors Tian Li and Shuaiming He, have been working with wood for many years. Hu’s team has invented a range of emerging wood nanotechnologies including a transparent wood, low cost wood batteries, super strong wood, super thermal insulating wood, and a wood-based water purifier.

“This is another major advancement in wood nanotechnologies that the Hu group at University of Maryland achieved: cooling wood that is made of solely wood – that is, no any other component such as polymers – can cool your house as a green building material,” said Hu.

WATCH: Researchers make really cool wood for energy efficiency https://go.umd.edu/coolwood

The team at Boulder, led by Professor Xiaobo Yin and co-first author Yao Zhai, both of the of the Department of Mechanical Engineering and the materials science program, have been working on materials for radiative cooling, including thin films and paints.

By removing the lignin, the part of wood that makes it brown and strong, the researchers created a very pale wood made of cellulose nanofibers. They then compressed the wood to restore its strength. To make it water repellent, they added a super hydrophobic compound that helps protect the wood. The result: a bright white building material that could be used in roofing to push away heat from inside the building.

The team took the cooling wood to a farm in Arizona, where the weather is always warm and sunny, with low winds. There, they tested the materials and found that it stayed, on average, five or six degrees cooler than the ambient air temperature – even during the hottest part of the day. The cooling wood stayed on average 12 degrees cooler than natural wood, which warms up more in the presence of sunlight.

“The processed wood uses the cold universe as heat sink and release thermal energy into it via atmospheric transparency window,” said Li. “It is a sustainable material for sustainable energy to combat global warming.”

The mechanical strength per weight of this material is stronger than steel, roughly ten times stronger than natural wood, and beats steel’s strength, reaching 334 MPa·cm3/g (compared to 110 MPa·cm3/g for steel). It also damages less easily and can bear more weight than natural wood.

Other collaborators include UMD’s Jelena Srebric and her College Park team; Ronggui Yang’s team at the University of Colorado, Boulder; and Ashlie Martini’s team at the University of California, Merced.

To see how much energy cooling wood saves, they calculated how much heat is used by typical apartment buildings in cities across the U.S. in all climate zones. Cities boasting high temperatures, such as Phoenix and Honolulu, would save the most energy, especially if older buildings had their siding and roofing replaced with cooling wood. Buildings across the U.S. that were built after 2004 would save on average 20% of cooling costs.

The research was funded by the University of Maryland.

A company co-founded by Dr. Hu, Inventwood (www.inventwood.com), is focusing on the commercialization of advanced wood nanotechnology.

For additional information:

Li, Zhai et al. (9May2019). “A Radiative Cooling Structural Material,” Science.

Published May 28, 2019