News Story

Simple and robust models of diffusion coefficients developed for metals and alloys

Professor JC Zhao, Chair of the Materials Science and Engineering Department at University of Maryland (UMD) College Park and his postdoctoral researcher, Dr. Wei Zhong, have developed new and very simple models to mathematically describe the diffusion coefficients of metals and alloys as a function of composition and temperature.

Many materials processes such as melting (casting), homogenization, precipitation, coating-substrate interaction, and creep deformation are dictated by the rate of diffusion of various elements in an alloy. Thus, diffusion is a fundamental process in alloys, and as a matter of fact, a fundamental process in nature. Diffusion coefficients are employed to mathematically describe the complex diffusion process, especially in solids, that involves the amount of vacancies available at a certain temperature and composition, the ability and frequency of an atom to jump to a neighboring vacant site in a crystal lattice, the rate of intermixing of different elements under a composition gradient, and the attractive or repulsive forces among the different elements.

Metallurgists often mix different elements in the Periodic Table to form the so-called solid solutions where different elements are mixed often quite randomly in crystal lattices. Solid solutions are a fundamental venue for metallurgists to tailor the strength, ductility, fracture toughness, and oxidation resistance of alloys. In a sense, solid solution is the concept of “alloying” and it is also the basis to induce precipitates to further strengthen alloys by means of the solubility difference of solid solutions at different temperatures. When two and three elements are mixed, their mixtures are termed binary and ternary solid solutions, respectively. Mixing of more than three elements leads to multicomponent solid solutions.

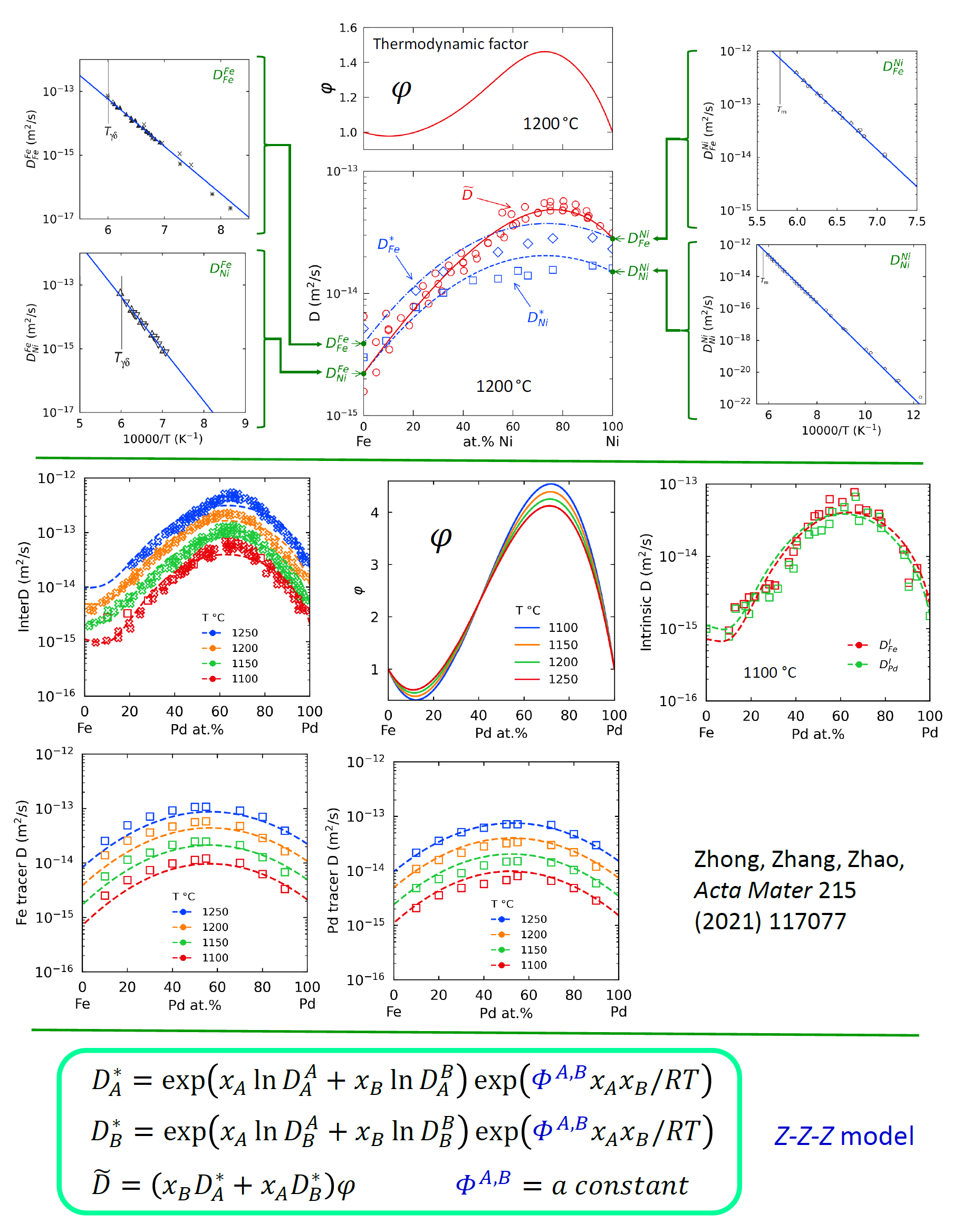

Seventy-three years ago (1948), Dr. Lawrence Darken employed Einstein’s relation to elegantly separate the thermodynamic contributions to diffusion from the purely kinetic contributions, leading to the famed Darken’s equation. The work was a giant step forward in understanding the complex diffusion process in binary solid solutions, and was hailed as one of the most influential studies in the field of metallurgy. Metallic elements, in a sense very similar to people, either like or dislike each other. For instance, gold likes copper, but dislikes nickel; leading to attractive or repulsive interactions which further lead to acceleration or deceleration of diffusion as the different elements attempt to mix. The thermodynamic factor defined by Darken accurately describes such thermodynamic contributions to diffusion.

About 40 years ago (1982), John Ågren expanded the Darken’s equation into ternary and multicomponent solid solutions using the Onsager formalism. Subsequently, Jan‐Olof Andersson and John Ågren in 1992 systematized the concept of atomic mobility that is widely adopted by the metallurgy field, especially the CALPHAD (calculations of phase diagrams) community. The parameters in their semi-empirical models are fitted from experimentally reported diffusion coefficients. Four or more, up to eight, fitting parameters are often employed in diffusion coefficient assessments in the literature for binary solid solutions, and up to 23 parameters are used for ternary solid solutions.

By collecting the most amount of available data and performing the most extensive testing of models with various number of parameters, Zhao’s group discovered that a simple one-parameter model works like wonder for each binary solid solution. The new model is dubbed as the Z-Z-Z binary model. Furthermore, a simple combination of the binary Z-Z-Z model parameters without any ternary-related fitting parameters is able to predict the diffusion coefficients of ternary solid solutions with very impressive results, leading to the Z-Z-ternary model. These models can be readily applied to multicomponent solid solutions and drastically reduce the number of fitting parameters while increasing the robustness of the prediction of diffusion coefficients.

These new models are developed very timely as the metals community is pushing to design the so-called high-entropy alloys (HEAs), or the multi-principal element alloys to take advantage of the vast composition space in the middle of the multicomponent element space in contrast to traditional alloys where one base element such as iron or aluminum dominates. The new models will enable diffusion coefficient databases to be more efficiently and more reliably established for HEAs.

The study was published as a two-part series in Acta Materialia, the most highly cited journal in the field of metallurgy, and in its sister journal Scripta Materialia. Zhao’s former graduate student and former postdoctoral researcher, Dr. Qiaofu Zhang, who now works at QuesTek Innovations LLC, was also involved with the model development for the binary solid solutions.

“We were quite surprised that such simple models work so well and there are still such beautiful gold nuggets to be discovered after the topic of diffusion in metals has been studied for more than a century,” said Zhao. “I am very confident that our models will be covered in future textbooks that deal with kinetics and diffusion behaviors in metals and metallic alloys. These models will substantially simplify future modeling of kinetics in alloys.”

Dr. Zhong stated that “What our models are saying is that when the thermodynamic factor is modeled properly, the pure kinetics of atomic mobility can be modeled with a simple function with only one parameter for each binary solid solution.”

The team is in the process of using data analysis, machine-learning and first-principles calculations to evaluate such a parameter in the near future. During the summer of 2021, both a high school student and an undergraduate student were provided research assistantships to help collect and digitize more experimental data from the published literature for such a study. If the parameter can be evaluated without experiments but be validated with experimental measurements, future establishment of the all-important diffusion databases will be easier and more reliable for computational alloy design.

This study was funded by the National Science Foundation (NSF) through a grant (#1904245) from the NSF Division of Materials Research (DMR). It was performed mostly during the COVID-19 pandemic when the experimental research was partially halted and delayed for months. Dr. Zhong was able to focus on the model development while working from his apartment. He developed a Python code to enable rapid testing of various models using thousands of experimental data points collected from the literature over the years. The study is the most extensive testing of models for diffusion coefficients in the world. In a way, the pandemic has accelerated the development of these models.

“I am in the process of making the Python code more user friendly and will share it freely and openly in the near future,” said Zhong.

“Even for a bad event like the COVID-19 pandemic, there is always positive outcome if we focus on opportunities and not be too distracted by the negative aspects,” Zhao added.

As an interesting note, both Dr. Lawrence Darken and Dr. John Ågren won the prestigious William Hume-Rothery Award that “is presented annually to recognize a scientific leader for exceptional scholarly contributions to the science of alloys” by the Minerals, Metals and Materials Society (TMS). Darken won the award 42 years ago back in 1979 and Ågren in 2011. Dr. Zhao was honored with the same pinnacle award this year and a three-day symposium was held in his honor during the 150th TMS Annual Meeting in March 2021.

“We stand on the shoulders of these two giants and take a small step forward to make future modeling of diffusion in alloys a bit simpler,” said Zhao. “The bottom line is that diffusion kinetics behaves much more ‘regularly’ than we have long thought, which is a very good thing. Mother Nature is quite kind to us in this regard.”

Published October 5, 2021