News Story

Atoms-Thick Coating Ready for First Test on Silver Artifact

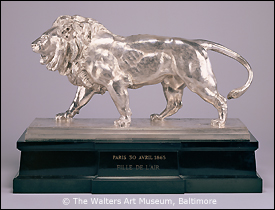

This elaborate processional cross from Zaragoza, Spain, is made of silver and enamel over a walnut wood core, radiocarbon dated to the late 15th century. It will be the first artifact from the Walters' world-class collection to receive a coating via atomic layer deposition to protect it from tarnish. Overall: 63 1/2 x 23 1/2 x 7 9/16 in. (161.3 x 59.7 x 19.2 cm). Purchased by Henry Walters circa 1909. Credit: Walters Art Museum.

"Our focus is long-term preservation of the objects in our care...Recent work has demonstrated that an ALD coating protects silver significantly longer than nitrocellulose, and that it coats the surface thoroughly with a layer of material that can be removed with negligible effects on the underlying silver."

Terry Drayman-Weisser, Walters Director of Conservation & Technical Research.

The important milestone in the ongoing collaboration between the Clark School's Department of Materials Science and Engineering (MSE), the Walters, and E-squared Art Conservation Science was recently reported by Science, both online at ScienceNOW and in its March 29, 2013 print edition, following a press briefing at the national meeting of the American Physical Society (APS).

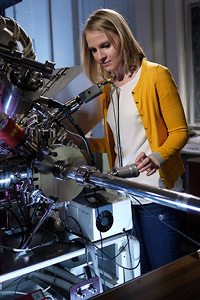

Since 2010, the research group, one of the first to be funded by the National Science Foundation's SCIART grant program, has sought a more effective solution to a problem faced by many museums: the threat of tarnish. Currently, silver objects are most often either painstakingly hand-coated or sprayed with nitrocellulose lacquers that begin to discolor or break down after about 20 years (at which point they must be cleaned and coated again), or kept in special exhibition cases. MSE professor Ray Phaneuf and his collaborators have been using a technique called atomic layer deposition (ALD) to apply coatings of aluminum oxide onto silver in layers measuring only atoms thick. The coatings are transparent, optimized to reduce the rate of corrosion, durable but easily removable, harmless to the artifact, and estimated to last at least 80 years.

Phaneuf describes ALD as providing "an exquisite level of control" that allows them to consistently apply coatings to the finest and deepest nooks and crannies in a way a conservator's brushes cannot.

The team first tested their coatings on small samples of fine and sterling silver, tooled in ways designed to simulate the complex surfaces of sculptures, utensils and jewelry. They simulated the passage of time on the coatings using accelerated testing techniques that exposed the treated samples to tarnish-inducing conditions: environments containing 100,000 times the natural concentration of hydrogen sulfide found in the atmosphere, or temperatures of 150 degrees centigrade. Using kinetics models, the results were translated into how long an equivalent amount of tarnish would take to build up at the concentrations and temperatures found in a museum.

Finally, they tested the removal of the coatings. "Copper depletion at the surface of our test subjects was the main concern," says project team member Eric Breitung of E-squared Art Conservation Science. "Through multiple tests, we found that only a few nanometers' worth might be removed during removal of the ALD coating, whereas polishing removes hundreds of nanometers of both copper and silver from the surface of an object."

After extensive experimentation, Terry Drayman-Weisser, Walters Director of Conservation & Technical Research, recently approved the application of the ALD treatment to one of the silver plates covering the wooden core of a late 15th century Spanish processional cross. The small piece of metal will be the first object from the museum's world-class silver collection to receive the new protective coating.

The Walters’ role in the project, she says, has been to bring professional conservation concerns to the table.

"Our focus is long-term preservation of the objects in our care," she explains. "Tarnishing of silver is problematic since polishing, even with mild abrasives, removes metal leading to loss of surface detail, and protective lacquer coatings can encourage severe corrosion if areas are missed during the application process. This is what has made the investigation of the ALD process appealing. Recent work has demonstrated that an ALD coating protects silver significantly longer than nitrocellulose, and that it coats the surface thoroughly with a layer of material that can be removed with negligible effects on the underlying silver. Although the process will not be appropriate for all silver objects and evaluation continues, we now feel confident in testing ALD on a piece from our cross.”

Walters Art Museum conservation scientist Glenn Gates explains the cross was chosen because the plate can be easily removed for coating and is small enough to fit in the university's ALD chamber. Because the cross is adorned with many strips of sculpted silver, the condition of the newly treated piece can be compared to others of the same age, origin and quality.

"The adjacent strips have the traditional nitrocellulose coating, so conservators and curators will be able to determine the visual suitability of our coating in a 'real-life' situation," says Gates, adding that after treatment, the cross will be on display in the Walters' Northern Realism gallery.

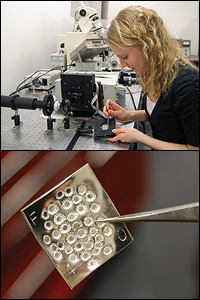

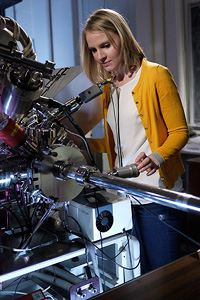

MSE Graduate student Amy Marquardt, who has worked on the project for the past three years, says the observation phase will be a crucial step in determining whether appearance of the ALD film on an object is aesthetically pleasing enough to be widely adopted. Ideally, the coating will not reflect light in a way that affects the apparent color of the piece, or that makes it too shiny or too dull.

In addition to Breitung, Drayman-Weisser, Gates, Marquardt and Phaneuf, the team includes Professor Gary Rubloff (MSE and Director, Maryland NanoCenter).

For More Information:

See ScienceShot: "Atomic Science Keeps Silver Shining Bright," online at ScienceNOW »

Wade, Lizzie. Random Sample: Atomic Science Keeps Silver Shining Bright. Science 29 March 2013: 1539.

Amy Marquardt, Eric Breitung, Glenn Gates, Terry Weisser, Gary Rubloff and Ray Phaneuf. "Effective Lifetimes of Atomic Layer Deposited Diffusion Barrier Films for Silver Artifacts." Bulletin of the American Physical Society 58(1). APS March Meeting, Baltimore, Maryland, March 2013. Abstract »

Visit Professor Phaneuf's web site »

Published April 19, 2013