News Story

MSE Capstone 2009

The 2009 Capstone team members present their research.

The team of six students—Jeremy Cheng, Sara Clementson, Grant Hatcher, Hilary Lane, Ryan Mullholland and Swezin Than Tun—chose the design of a particle reinforced shape memory polymer stent for their project.

Stents are medical devices that are inserted into blood vessels to reverse constriction, most often caused by atherosclerosis, which is the buildup of cholesterol plaque on the inner walls. In the 1970s, angioplasty was developed to expand the constricted artery using a small balloon. However, the use of angioplasty alone is not effective because constriction reoccurs within the first six months in 30-60% of patients who undergo balloon angioplasty alone. Metallic stents were first introduced in 1986 and today up to 800,000 procedures involving stents are performed annually. Commercially available stents have undergone many design improvements since they were first introduced, but they still do not incorporate all of the features that are desirable in stent design. Modern stents can cause artery damage due to rapid expansion or size mismatch, can contain only minimal drug loading, require prolonged antiplatelet therapy, and require relatively large catheters and incision sites for insertion.

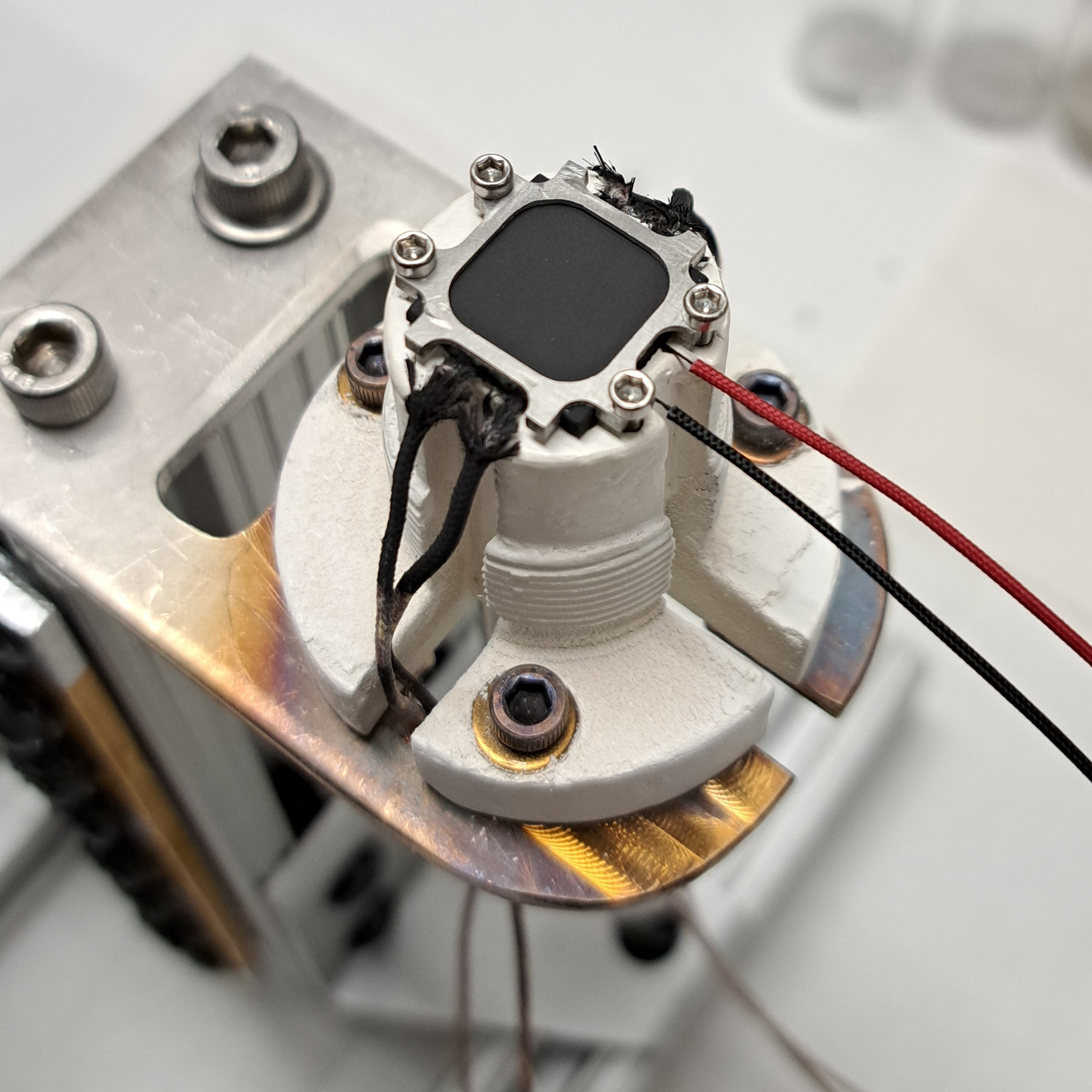

Shape memory polymers present a novel solution to many of the problems associated with metallic stents. Shape memory materials are those that can recover their original shape or state after significant mechanical deformation. This effect in polymers is usually initiated through a temperature change, but can also be triggered by light or a local change in chemical environment. Unlike shape memory alloys, the effect is not due to a phase change and larger recoverable strains can be achieved (up to 400%). These materials expand more slowly than shape memory alloys, reducing the probability of arterial damage during insertion, and they more closely match the compliance of the artery without high local pressures. A common concern with the use of polymers in this application is their ability to withstand the pressures placed on it by the artery without collapsing inward.

During their presentation, the seniors described the fabrication and testing of samples of shape memory polymers with different amounts of crosslinking, and different amounts of reinforcing particles to determine the mechanical properties for their computer modeling and simulation of the response of a stent to external pressure. They were able to determine the minimum stent wall thickness beneath which a stent might collapse by "buckling". They also described lessons learned in Capstone process.

"They accomplished an impressive amount of work, both in the lab and in their simulations in spite of time constraints," said Associate Professor Ray Phaneuf, who advised the team.

For More Information:

Published May 21, 2009